工作原理:

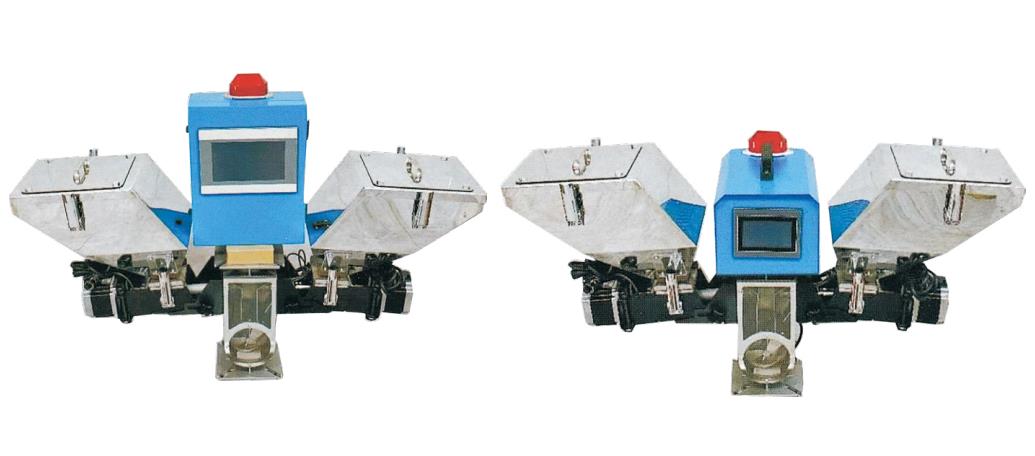

Cm 系列色母计量机适用于塑料成型生产中的新、次料,色母或添加剂等的自动比例计量喂料。该系列机型采用精密直流无刷式马达。根据预先设定的添加比例和参数,由全数字式微电脑控制系统将设定的各项条件自动转换成转速,通过联轴器驱动不锈钢304 精密计量螺杆,向注塑机或挤出(压延)的溶胶简内吐出需要添加的物料。例如:色母色料、回收(水口)料、添加剂、助剂等。其误差值不高于 1%,该产品具备两种模式,分别适用于塑料的注塑成型和挤出成型。计量螺杆分为 12、16、20、24 等多种,直流无刷电机搭配不同减速比的高效平行齿减速机。可衍生出多种机型,提供 0.1-100kg/h 的不同输出量供客户选择。另有双色、三色四色博伊德赌场,根据用户需求搭配,满足不同场合、不同领域的使用。

REMARKS:

Cm series color master metering machine is suitable for automatic proportioning feed of new, secondary materials, color master or additives in plastic molding production, This series of machine adopts precision dc brushless motor. preset The fixed addition proportion and parameters are automatically converted into the speed by the all- digital microcomputer control system, The stainless steel 30recision measuring screw is driven by the coupling to the injection molding machine or extrusion(calendering) the material to be added is ejected from the sol cylinder,For example: color master batch,recovery (water port) materials, additives, additives, and so on. It’s error value is not more than 1%,this product has two modes,cent Do not apply to plastic injection molding and extrusion molding.The measuring screw is divided int 12, 16,20, 24 and so on, the de brushless motor is matched with different deceleration ratio of efficient parallel teeth reducer, There are many variations The model provides different output quantities of 0. 1- 100ka/h for customers to choose There are two -color three -color four -color master machine. According to user demand match, meet different occasions different fields of use.

产品特点:

1)采用直流无刷式电机,无需保养,具有螺杆卡料、电压欠压,过压、过流、断线保护,保证机器连续正常运行。

2)控制器具备 20 组数据的久远记忆及存储功能,方便管理成型条件和配方。

3)可满足注塑机干接点和电压,挤出机 0-5V、0-10V、4-20MA、0-20MA、频率、数字等多种信号输入,几乎涵盖所有塑料成型设备的塑化信号(需提前告知信号类型)。

4)模块式装配结构,拆装方便,可快速更换物料。

5)可选配物料料位检测传感器,缺料报警提示。

6)可选配搅拌底座,确保物料混合均匀。

7)可于挤出(压延)机主螺杆同步加、减速运行。

8)控制器独特的补偿优化理念,保证添加物的计量始终精准。

9)离线模拟功能,设备调试过程中,可快速调整添加物至理想份量,减少调试过程材料的损耗,大大降低换料调试时的人力以及物料消耗。

10)可配合化纤丝单丝、长丝纺丝设备使用的特殊模式,能确保纺丝设备各熔体计量泵随意调速始终保证高稳定性的助剂添加。

11)带扩展功能的特殊控制器可选配称重控制模块,实现添加料比例的数字化控制,更大程度上保证计量的准确性。

12)落料结构经过优化和改良设计的加强型安装底座,确保大色母用量也能正常使用,即使是大用量的回收料,同样可以适应。

PRODUCT FEATURES:

1)Adopt brushless de motor,without maintenance,with protection of screw clip,voltage undervoltage, overvoltage, overcurrent and broken wire,to ensure the continuous normal operation of the machine.

2)The controller has the permanent memory and storage function of 50 sets of data to facilitate the management of molding conditions and formulations.

3)It can meet the dry contact and voltage of the injection molding machine and the input of various signals such as 0-5v,0-10v,4-20ma,0-20ma,frequency,digital and so on of the extruder,covering almost all plasticizing signals of plastic molding equipment(signal type should be informed in advance).

4)Modular assembly structure,convenient to disassemble and assemble,and quick to replace materials.

5)The material level detection sensor can be optional,and the alarm for missing materials can be given.

6)Mixing base is optional to ensure uniform mixing of materials.

7)Can simultaneously add and slow down the main screw of the extruder (rolling).

8)The unique compensation and optimization concept of the controller ensures that the measurement of additives is always accurate.

9)Off-line simulation function: in the equipment debugging process, it can quickly adjust the additive to the ideal amount, reduce the material loss in the debugging process, and greatly reduce the manpower and material consumption during there fueling and debugging.

10)The special mode that can be used in combination with chemical fiber single -wire and filament spinning equipment can ensure that the melt metering pumps of the spinning equipment can adjust the speed at will and always ensure high stability.

11)Special controller with extended function can be equipped with weighing control module , which can realize the digital control of the proportion of added materials and ensure the accuracy of measurement to a greater extent.

12)The strengthened mounting base of the feeding mechanism, which has been optimized and improved, ensures the normal use of the large color master batch.which can be adapted even for the recycling materials in large quantities.

免责声明:(1)以上所展示的信息由企业自行提供,内容的真实性、准确性和合法性由发布企业负责,博伊德赌场网对此不承担任何保证责任。我们原则上建议您优先选择“塑企通”会员合作! (2)同时我们郑重提醒各位买/卖家,交易前请详细核实对方身份,切勿随意打款或发货,谨防上当受骗。如发现虚假信息,请向博伊德赌场网举报。

免责声明:(1)以上所展示的信息由企业自行提供,内容的真实性、准确性和合法性由发布企业负责,博伊德赌场网对此不承担任何保证责任。我们原则上建议您优先选择“塑企通”会员合作! (2)同时我们郑重提醒各位买/卖家,交易前请详细核实对方身份,切勿随意打款或发货,谨防上当受骗。如发现虚假信息,请向博伊德赌场网举报。

簡繁切換

簡繁切換